We Are The Creators You Can Trust On For A Perfect Solution To All Your Needs.

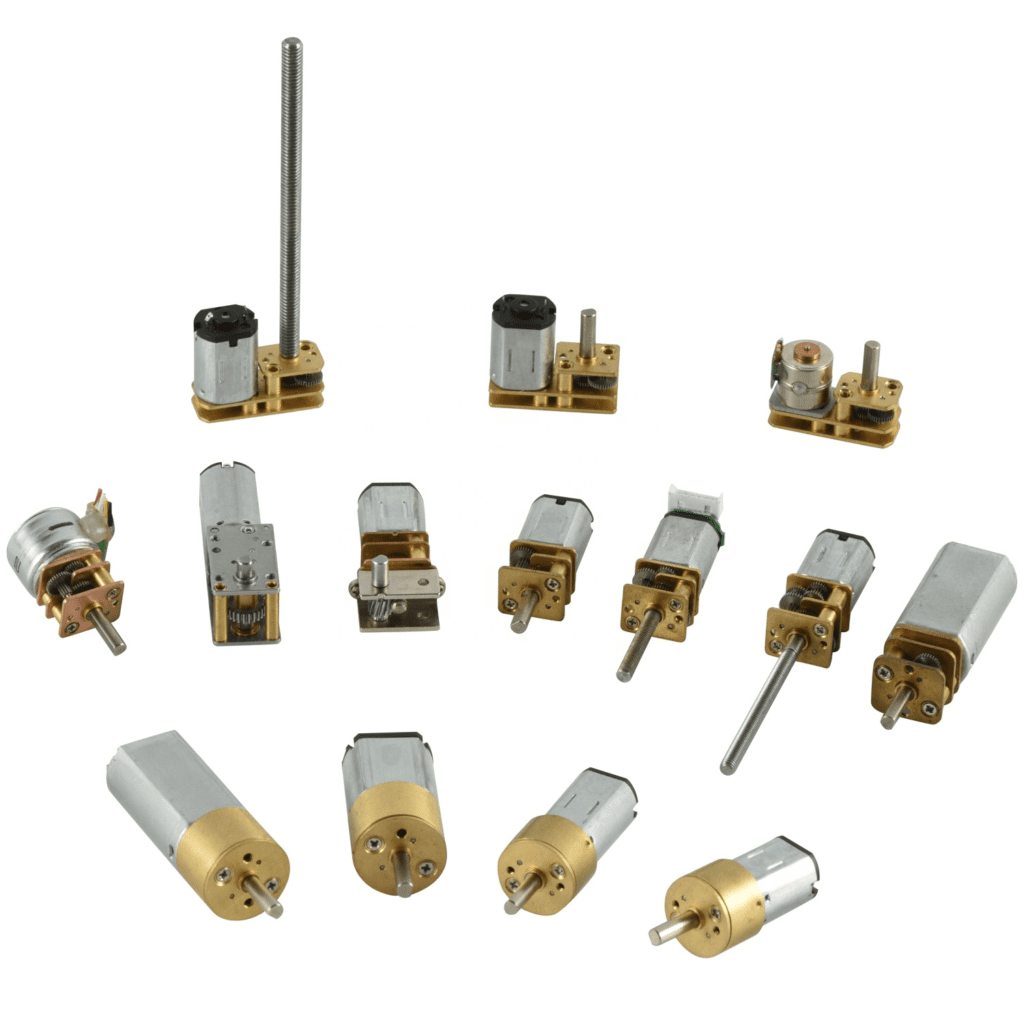

Dc Gear Motor

Micro geared motor with high precision, low noise, long life, its application areas are also very wide. For example, office automation, electronic door locks, electric curtains, intelligent toys, medical equipment, vending machines, etc.

Hot Product From Customer's Feedback

We only provide motors with over-products, and if you need other accessories, we can also meet you. Please check the motor accessories page under our product page.

N20 gear motor 12mm

EL16GA030 gear motor

EL-4058R370 worm gear motor

ELDG25A-370 motor

ELGM12-1024 threaded shaft

ELPG120-N20 planetary motor

Our geared motor has a series and modular design, with wide adaptability. Also can combine a variety of other motors, device orientation and layout plans. Any speed and various layout methods can be selected according to actual needs.

- Light weight and easy to install.

- Stable performance, high transmission accuracy, and instantaneous conversion are possible.

- High efficiency, power saving and low heat generation.

- Good starting performance and high torque.

- Low noise, high transmission efficiency and low energy consumption.

- Miniature geared motor is simple in structure, easy to use and maintain.

- Small control power, easy for self-control, group control and remote control.

.

Estimated Cost

Customize Fee

For some unusual products, additional abrasive costs may be incurred. This cost will need to be priced by our engineers and material supplier’s accounting.

Sample Fee

We can provide free samples of up to five. If you need more samples, you will pay petty expenses. We will credit this sample fee when you place your official order.

Shipping Fee

The shipping fee from the China shipping company warehouse to your company will be paid by you. If you have another way, we will coordinate with you.

Payment Term

30% initial payment should be paid before order materials, and the balance will be paid before shipment.

Need More Specific Details?

Estimated Produce&shipping Time

We try to schedule each order as quickly as possible. Our staff will follow up your order in real time and keep in close contact with the factory as a way to avoid delays that may occur. Let’s take a brief look at the process.

Step 1

Order materials and production time (7-15 days)

It usually takes 7-15 days to order materials. After receiving the material, our factory will check it is in good condition and arrange production.

Step 2

Package Time(1-2days)

After the products are finished, the staff will do the boxing work in the shortest possible time.

Step 3

Loading time (3-7 days)

Our staff will send the loaded goods to the designated warehouse of the shipping company and handle all the work matters before loading. The specific sailing time is subject to the arrangement of the shipping company. Under normal circumstances, the ship will depart within 1-2 weeks.

Step 4

Express, air, land and sea freight times

The specific timeframe differs for different modes of transportation. During the transportation of the goods, our staff will keep you informed of the exact destination and location of the goods.

Need Sample Before Order?

Before placing the order, how can you determine if the motor meets the requirements? You need to get samples to verify the quality is acceptable. Elmotorio can supply a few free samples for you.

If the sample doen’t suit for your enginee or needs to be improved, please give us your opinions in time. We will slove the related and re-samples as soon as possible.

Whole production process

Raw Materials

Winding

Testing

Punching

Rotor Welding

Spray Code

Rotor Making

Maganization

Package

End cap:Product drawing outsourcing casting blank parts, castings qualified into the factory, for machining. Process route: Casting – turning – drilling

Machine base: Product drawing outsourcing casting blank parts, castings qualified into the factory, for machining. Process route: Casting – lock or turning – milling – drilling – tapping.

Stator winding: Outsourcing enameled wire for winding according to the product specification drawing requirements.

Stator rotor punching: Outsourcing electrical silicon steel plate cylinder coil material, cut the ordered material according to the process material arrangement chart, and then carry out the drop material punching slot. Process route: ordering material – drop material – punching slot

Stator core with winding: After the stator punching sheet is stacked and cleaned by hydraulic press and process tooling, the stator coil is embedded with the rapped stator coil, wired and tested for ground voltage breakdown, and insulated after passing the test. Insulation treatment through the equipment for dipping paint, baking process means to improve the insulation of the motor. Process route: piece – stacking – cleaning – inlay – wiring – test – dip baking – sand paint.

Casting aluminum rotor: Aluminum ingots are purchased, dissolved in medium frequency furnace, die-cast by die-casting machine, and secondary cast shaft. Process line: sheeting – die-casting – cleaning – secondary heat sleeve.

Rotor shaft: Outsourcing billet round steel, ordering material according to process size, adjusting heat treatment process according to technical requirements of drawings, and mechanical processing. Process route: ordering material – heat treatment – punching center hole – turning – grinding – milling

Rotor: After the cast aluminum rotor is heat-sleeved and qualified, it is turned and machined in the outer circle and calibrated for dynamic balance. Process route: Turning – cleaning – calibration of dynamic balance – painting.

Stator assembly and assembly: Use the stator press to press the core of the stator with winding into the cavity of the machine base, carry out junction box assembly, rotor threading, pressure bearing and other assemblies. Then the motor factory performance test, the test passed can be surface painting, otherwise re-servicing the motor. Process route: stator pressed into the chassis – assembly – test – painting – into storage.

Other parts: According to the different specifications of the motor required to be equipped with small parts for processing

Frequently Asked Questions

We supply DC motors and geared motors from 6 to 80mm. Motors for the automotive field are our strength. For other motors can be customized through us, and we can find the most suitable resources for you.

Our business is mainly based on wholesale. As a trading&manufacturing Combo., we may not be able to meet the requirements of some small retail buyers. Usually the minimum order quantity is 1000, and we can accept 500pcs for trial order.

Of course, we can certainly support such service. You just need to provide the corresponding number or content to us, adn we will arrange to change the spray code.

Please let us have the specifications of the specific motor and the material so that we can estimate the price. We don’t over cost and we strive to be realistic. We can check the most moderate price according to the customer’s requirements.

We also will meet some clients have demand of accessories, so these accessories are included in our business.

Welcome to consult us

Address

3D-03, 3/F, Building A (Lobby B), Wanxin Commercial Plaza, No.22 Center Road, Xinqiao Street, Bao'an District, Shenzhen, Guangdong, China

info@elmotorio.com

Phone

+86 13066810201